A tungsten light is, in most cases, some variation of parts built around 3 basic sections: a plug, some wire, and a bulb. This is super simple tech and repairing it is equally as simple. But what happens when something goes wrong on your LED panel? Where does somebody even start diagnosing the problem? LED fixtures are literally computers with lights attached to them and need to be treated as computers when fixing them. This month, I was lucky enough to have the opportunity to be invited to one of Arri’s US repair facilities to get a chance to see what is under the hood of their L-Series and Skypanel LEDs.

Arri’s US East Coast service center is located in Blauvelt, NY and is one of just three Arri service centers in all of North America. Having such a resource so close to our backyard was a blessing we were lucky to have and more than happy to take advantage of. There were a bunch of attendees from different backgrounds in the industry from the Northeast and as far away as California and Georgia.

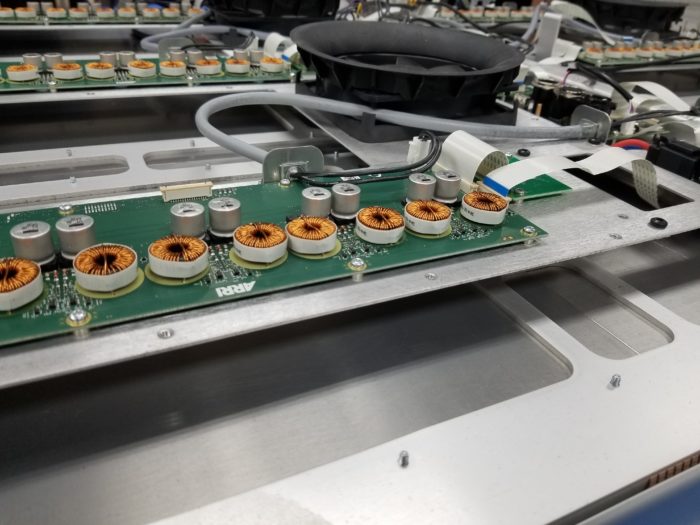

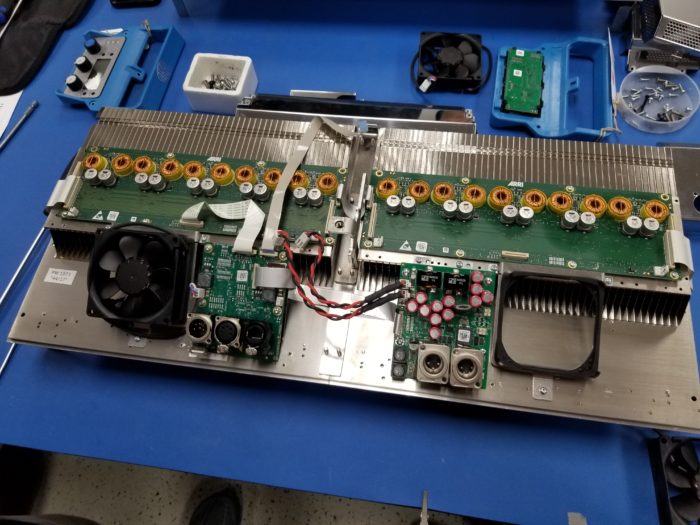

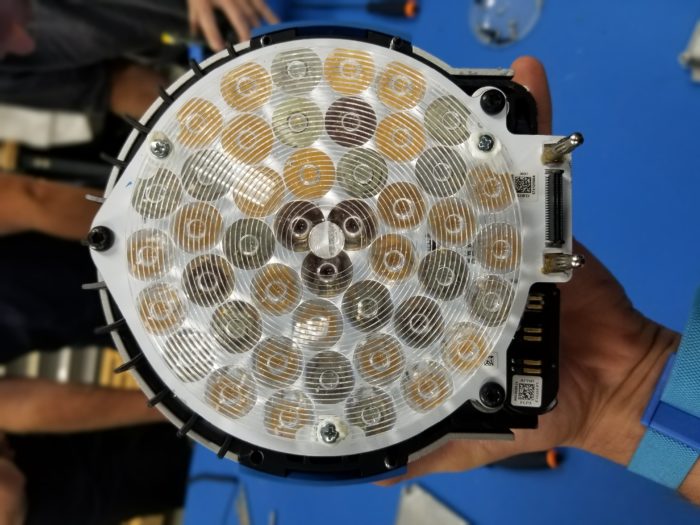

The inside of these things isn’t what you might think – more than just a circuit board and an LED, they consist of a complex series of parts that make the light work. Power is brought into the unit and into the boost board which then sends power through the rest of the unit. The controller at the top sends information to the control board which then relays that info to the drivers which tell the light engines or LED’s how to output light. The L-Series works roughly the same way except that the light engine is a little different and sends the light through a fresnel lens. All of this technical stuff is just to say that there’s a lot that goes into these things which also means that there are a lot more places for things to go wrong.

By far the most constructive part of the training was, ironically, the most destructive. Learning how to disassemble the units and reassemble them was invaluable as a technician and gave a much better understanding of how the units worked from a base level. For example, learning more about the fans. I’ve always known that the Skypanel is essentially a big computer with fans and heat sinks, but with that knowledge comes the understanding that you must treat it as such. The fans bring in fresh air to cool the heat sinks, but they also bring in any other particles in the air.

The instructors told us about a rental house in Europe that had 80 Skypanel units on a studio shoot. The scene was a winter shot using multiple fake snowmakers. After the shoot, the Skypanels were packed up and shipped to another shoot in Southeast Asia where they promptly laid a giant egg and died. When they were opened up, repair techs realized that the insides of the Skypanels were corroded with entire power runs completely eaten away in some cases. The fans had been drawing in all of the moisture from the fake snow on that previous studio shoot. This by itself wouldn’t have been the end of the world if they had been wiped down immediately afterward, but the technicians let the panels air dry. By letting the snow air dry, the sediment in the moisture was left to build up on the internal components of the panel. Worse, the units were packed into their cases immediately after the shoot which kept the moisture on the units even longer. Knowing now how the fans work, I’d be able to warn operators against these kinds of situations and prevent catastrophic damage to the units.

Being able to speak directly to instructors from Arri’s headquarters in Munich was incredibly worthwhile and almost worth the price of the course alone. I’ve learned what I know about the operation of the L-series and Skypanels from industry gaffers and set technicians, but being able to have questions answered by the people from the facilities where these technologies were developed was really special. And seeing the looks on their faces when they learned how some set technicians handled their units in the field was priceless. Like hearing about gaffers booming Skypanel 360’s straight out from their condor boxes. Or operators removing the diffusion panel for a “boost” in output (PRO TIP: This is a myth. Output is actually slightly worse with bare diodes). Having the thought processes behind the design of the fixtures explained as well as the difficulties faced in their construction, such as the water-proofing attempts for the L7 or the differences in the layout of the light engines between Skypanel models, just added another layer to understanding how the lights work and the limitations that each fixture has.

Perhaps the most important aspect of the training is that it now allows me, and Expressway by extension, access to parts and tools only available to Arri service partners such as boards and thermal paste templates. All of these parts are delicate, complex and expensive. You know, the kinds of stuff I shouldn’t be trusted to handle…until now. Having the knowledge to repair and access to parts lets us keep our lights on set instead of on a shelf and keeps you from having to find some other big, soft light to do all your fancy color runs on.

Being certified as an Arri repair specialist isn’t just beneficial to Expressway, it’s beneficial to the Philadelphia film community as a whole. Previously, repairing any Arri LED fixture would require it being sent away to Blauvelt which would put it out of commission for weeks due to the sheer volume of repairs at the facility. Now, customers can have the fixture sent to us. Lower volume of repairs and closer proximity reduces wait times for repairs to be done ensuring customers can have their fixtures back sooner and in good condition to begin shooting again.

This training course wasn’t just instructive, it was a lot of fun too. It was cool meeting other technicians from around the country and working and learning together while also sharing our own knowledge and stories with one another (and by sharing stories, I mean complaining about terrible repairs we’ve had to make). Working together during the two days, we were supportive in helping one another when someone may have missed a step but also had fun ripping on each other when someone forgot to put a screw back in the correct way or laughing at our terrible pronunciation of the German names for pieces and parts. To be fair though, how the hell would YOU pronounce Sechskantschraube? See, not so easy, right?

Expressway is always striving to provide a higher level of service to the Philadelphia filmmaking community, and continuously investing in our service department is a prime example of that. Learning the inner workings of the newest lighting fixtures isn’t just important for making repairs, it gives us an understanding of our fixtures at a component level that most other places just simply don’t have. LED technology is the present and future of set lighting and we need to continue to maintain our knowledge of these fixtures as we have with any other equipment in our inventory. It’s this attention to detail that helps define who we are as a rental house and can help us continue to provide top quality service to makers in the area.